Ever heard of dielectric grease and wondered what it’s for? If you’ve ever worked with electrical components, chances are you’ve come across this silicone-based substance. But what the heck is dielectric grease, really? Is it something you need in your toolbox, or is it one of those products you can skip? In this article, we’ll break down what it is, how it works, and whether it’s actually necessary for your electrical and automotive projects.

What Exactly Is Dielectric Grease?

Dielectric grease is a non-conductive, silicone-based lubricant that’s primarily used to protect electrical connections from moisture, dirt, and corrosion. Its main job? To ensure that your electrical components remain in tip-top shape while also making sure they don’t short out due to exposure to environmental elements.

The Composition of Dielectric Grease

It is made from silicone oil mixed with thickening agents. This gives it a gooey, gel-like consistency that makes it easy to spread over electrical components. The silicone base ensures that the grease can withstand high temperatures and resist water, making it an excellent insulator and protector.

How Dielectric Grease Works

Although dielectric grease doesn’t conduct electricity, it works as an insulator. By coating electrical connections with this grease, you create a protective barrier that prevents moisture and contaminants from getting in and causing corrosion or short circuits. This helps to maintain clean, strong connections while still allowing electrical current to flow properly through the metal parts.

Common Applications of Dielectric Grease

Dielectric grease is more versatile than you might think. It’s used across several industries, from automotive maintenance to household electronics.

Electrical Connections

One of the most common use is protecting electrical connections. If you’re working on wiring, particularly outdoors or in moist environments, dielectric grease can keep the connections dry and free from corrosion. It’s often used in wiring for lighting fixtures, antenna connections, or other exposed connections.

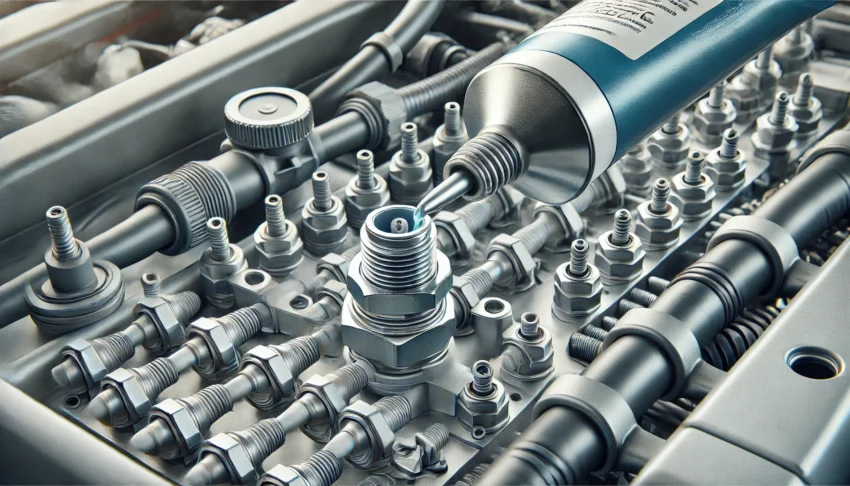

Automotive Uses

You’ll find dielectric grease in many automotive applications. It’s particularly useful for protecting spark plugs, battery terminals, and other connectors in vehicles. The grease seals out water and helps ensure your car’s electrical components function efficiently, even in harsh conditions.

Household and Commercial Uses

Dielectric grease isn’t just for mechanics. In homes, you can use it to protect wires in appliances, outdoor lighting, or even in your boat’s electrical systems. Commercial applications include protecting electrical systems in buildings and industrial equipment.

The Benefits of Using Dielectric Grease

What makes it so special? Its primary benefits lie in protection, performance, and longevity.

Prevents Corrosion

One of the biggest threats to electrical connections is corrosion, especially in damp or harsh environments. Dielectric grease acts as a barrier, keeping moisture and air away from the metal parts. This prevents rust and ensures the connections last much longer.

Enhances Electrical Performance

Since dielectric grease stops corrosion, it helps electrical connections perform better by ensuring they stay clean and free from obstructions. The grease keeps contaminants out, so your electrical components won’t experience issues like shorts or weak connections.

Extends the Lifespan of Components

Regular use of dielectric grease can extend the lifespan of your electrical systems. By sealing out damaging elements, the grease helps keep parts functioning longer, meaning fewer replacements and repairs over time.

Misconceptions About Dielectric Grease

There’s some confusion surrounding dielectric grease. Here, we’ll clear up two of the biggest misconceptions.

Does It Conduct Electricity?

No, it is non-conductive. Some people worry that applying it to electrical connections might prevent them from working properly, but the grease does not interfere with electrical flow. It simply protects the components from outside contaminants.

Can It Cause Short Circuits?

No, dielectric grease doesn’t cause short circuits. In fact, it prevents them. By keeping moisture out, it stops water from seeping into electrical connections and causing a short. However, you should always apply it properly to avoid buildup in areas that need direct contact.

Is Dielectric Grease Necessary?

The big question: Is dielectric grease something you actually need?

In Vehicles

When it comes to cars, the answer is often yes. If you live in an area with harsh weather or if your vehicle is regularly exposed to moisture, dielectric grease is crucial for protecting spark plugs, battery terminals, and other electrical components. Without it, you might find yourself dealing with corrosion and electrical problems sooner than you’d like.

In Electrical Systems

In outdoor or exposed electrical systems, dielectric grease can be essential for preventing corrosion and keeping your connections safe. For household wiring or everyday electronics, it’s often recommended to use it in places where connections are prone to moisture or dirt.

When It’s Not Necessary

However, there are situations where dielectric grease might not be needed. If your electrical systems are located indoors and aren’t exposed to the elements, you may not need to use it. Similarly, if you’re dealing with low-risk applications, the grease might be overkill.

How to Properly Apply Dielectric Grease

Its application is simple, but you want to do it correctly to avoid issues down the road.

Tools and Materials Needed

To get started, all you need is a tube of dielectric grease and a small applicator or your hands. It’s best to use gloves to keep things clean and avoid skin irritation.

Step-by-Step Application Guide

- Clean the area where you’ll be applying the grease.

- Apply a thin layer of dielectric grease to the metal parts of the connection.

- Make sure the layer is smooth and uniform, avoiding any buildup or excess that could cause clumping.

- Reconnect the components and wipe off any excess grease that might have squeezed out.

Alternatives to Dielectric Grease

While it is highly effective, some alternatives might work in a pinch.

Petroleum Jelly (Vaseline)

Some people use petroleum jelly as a quick, cheap alternative to dielectric grease. While it can offer some protection, it doesn’t have the same heat resistance or long-lasting properties as dielectric grease, so it’s not a perfect substitute.

Conductive Grease

Conductive grease is sometimes used for different applications where electrical conductivity is necessary. Unlike dielectric grease, which insulates, conductive grease allows electrical current to flow. However, it’s not suitable for protecting connections from moisture and corrosion.

Where to Buy Dielectric Grease

You can find it in most automotive stores, hardware stores, or online retailers.

Popular Retailers

Places like AutoZone, Walmart, Amazon, and Home Depot carry dielectric grease. It’s often located in the automotive or electrical sections of these stores.

Price Range and Sizes

Dielectric grease typically comes in small tubes, but larger containers are available for bigger projects. The cost varies, typically falling between $5 and $20, influenced by the brand and the quantity purchased.

Conclusion

Dielectric grease may seem like a small, unimportant product, but it plays a crucial role in protecting electrical systems. Whether you’re working on your car, boat, or household electronics, its usage can save you from dealing with corrosion, short circuits, and costly repairs. So, is it necessary? If you want to keep your electrical components running smoothly and lasting longer, then yes—dielectric grease is definitely worth having on hand.

FAQs

Is dielectric grease the same as silicone grease?

No, although they share similar properties, dielectric grease is specifically designed for electrical applications, while silicone grease is a more general lubricant used in various industries.

Can you use dielectric grease on battery terminals?

Yes, applying it to battery terminals helps prevent corrosion and maintains a strong electrical connection.

How long does dielectric grease last?

It can last several years once applied, as it is resistant to moisture, heat, and corrosion.

What are the potential consequences of not applying dielectric grease to your spark plugs?

Without it, spark plugs can corrode over time, which may lead to electrical misfires and reduced engine performance.

Can you use dielectric grease on computer components?

Yes, but with caution. It’s mainly used in connectors and not directly on circuit boards, as it’s non-conductive and can prevent shorts from moisture.