In modern vehicle manufacturing, automotive adhesive glue plays a crucial role in assembling, reinforcing, and repairing vehicle components. These adhesives offer powerful bond strength, replacing mechanical fasteners like screws, bolts, and welds.

Advancements in adhesive technologies have revolutionized automotive assembly by improving structural integrity, reducing vehicle weight, and increasing efficiency. Whether for structural adhesives, weatherstrip adhesive, or urethane repair material, selecting the correct adhesive is essential for safety and durability.

This guide covers everything about automotive adhesives, from their types and applications to bond strength and adhesion for metal and plastic surfaces.

Types of Automotive Adhesives

Automotive adhesives come in various types, each designed for specific applications and materials. Here’s a breakdown of the main types of automotive adhesives, their benefits, and their common applications in vehicles.

1. Structural Adhesives

Overview

Structural adhesives are designed to bear heavy loads and provide high bond strength. They are commonly used in critical automotive assemblies, replacing mechanical fasteners like bolts and welds.

Benefits:

Stronger bond than mechanical fasteners

Reduces vehicle weight, improving fuel efficiency

Prevents galvanic corrosion by eliminating metal-to-metal contact

Evenly distributes stress, improving fatigue performance

Applications:

Auto body panel adhesive for joining metal and plastic panels

Bonding process for chassis assemblies

Used in structural adhesive tapes for reinforcing vehicle structures

2. Epoxy Adhesives

Overview

Epoxy adhesives are two-part adhesives that form a powerful bond between various materials. They are known for high chemical resistance and durability.

Benefits:

Exceptional bond strength for metal-to-metal applications

Resistant to extreme temperatures and chemical exposure

Ideal for high-stress and high-load applications

Long-lasting durability

Applications:

Bonding process in automotive assembly line

Auto body repair and urethane repair material applications

Epoxy Adhesive DP420LH for metal bonding

3. Urethane Adhesives

Overview

Urethane adhesives are flexible, offering high impact resistance and vibration absorption. They are widely used in glass bonding and weatherproofing applications.

Benefits:

Highly flexible, allowing for movement and expansion

Excellent weather resistance (moisture, cold temperatures, UV)

Vibration damping, reducing vehicle noise and shocks

Strong adhesion to glass, metal, and plastic surfaces

Applications:

Weatherstrip adhesive for sealing doors and windows

Attach mirror in rearview mirrors installation

Bond with glass for windshield and bond exterior components

4. Acrylic Adhesives

Overview

Acrylic adhesives are fast-curing and highly versatile, working on plastic, metal, and composite materials.

Benefits:

Fast-drying adhesives, reducing assembly process time

High heat resistance (including black-coloured, high heat-resistant adhesive)

Strong adhesion to a variety of surfaces

Good resistance to salt water and boiling water

Applications:

Bonding of plastic surfaces in vehicle interiors

Used in cartridge adhesive and latex construction adhesive blue cartridge

Automotive contact adhesive for trim and decorative parts

5. Hot-Melt Adhesives

Overview

Hot-melt adhesives are thermoplastic adhesives applied in a molten state, solidifying upon cooling.

Benefits:

Rapid bond strength, improving faster cycle times

Excellent for flexible, semi-rigid, and rigid plastic applications

Strong adhesion to surface energy plastics

Applications:

Flexible and semi-rigid plastics in vehicle interiors

Automotive assembly of trims, badges, and lightweight components

Adhesive glue for quick repairs

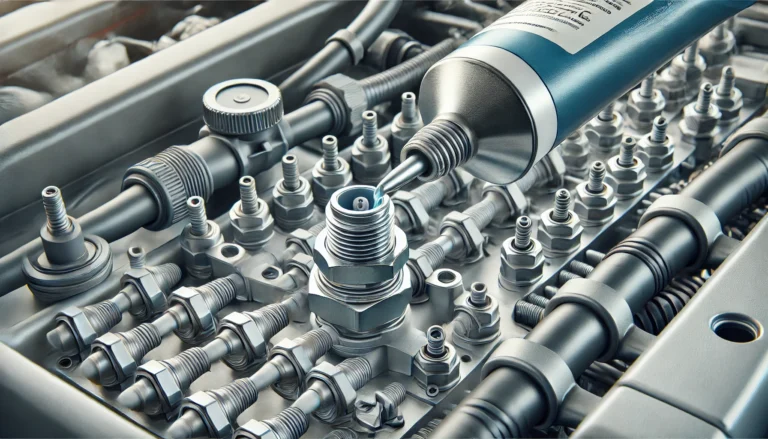

6. Anaerobic Adhesives

Overview

Anaerobic adhesives cure in the absence of air, making them ideal for sealing and locking threaded fasteners.

Benefits:

Prevents corrosion protection in fasteners

Stronger bond than traditional thread-locking methods

Resistant to environmental performance conditions

Applications:

Bolt adhesive 0.20 for conventional fasteners

Sealing leaks in automotive repairs

Adhesion of repair fillers for minor non-structural repairs

7. Conductive Adhesives

Overview

Conductive adhesives are used in electrical and battery applications, offering strong adhesion with conductivity.

Benefits:

Ensures electrical conductivity in circuits

Works well in electric vehicle batteries

Flexible working times for precision applications

Applications:

Bond battery packs in modern vehicles

Effective glass assembly for terminals against corrosion

Assembly of wires in automotive electronics

Advantages of Automotive Adhesives

Adhesive technologies have revolutionized automotive assembly, offering advantages that traditional fasteners cannot match.

- Weight Reduction: Adhesives replace conventional fasteners, reducing weight and improving environmental performance and fuel efficiency.

- Design Freedom: Using advanced adhesives allows for design freedom, enabling sleek and aerodynamic vehicle designs.

- Corrosion Resistance: Unlike mechanical fasteners, adhesives prevent galvanic corrosion, especially when bonding dissimilar materials like bonding of plastic surfaces and bond with glass.

- Extreme Temperatures & Weather Resistance: Adhesives maintain performance in cold temperatures, boiling water, and salt water conditions.

As the automotive industry shifts toward lighter and more fuel-efficient vehicles, adhesives play an increasingly vital role.

Challenges & Considerations in Automotive Adhesive Selection

1. Surface Preparation

For adhesive bonds to form properly, surfaces must be clean and free from contaminants.

2. Cure Time & Workability

- Fast-drying adhesives like black-coloured, high heat-resistant adhesive cure quickly.

- Flexible work times allow adjustments before setting.

3. Cost vs. Performance

- All-Purpose Adhesive may be affordable but lacks stronger bond properties.

- Anaerobic adhesives work well for bond dissimilar surfaces.

Application of Adhesives in Automotive Assembly

1. Bonding Process in Manufacturing

The assembly process includes:

- Surface Preparation – Cleaning the surface

- Adhesive Application – Using double-sided adhesive tape or bolt adhesive 0.20

- Curing – Allowing 10-15 extra minutes for optimal adhesion

2. Automotive Repairs & Emergency Fixes

- Auto body repair and common repair project solutions

- Emergency repairs using weatherstrip adhesive

- Cosmetic repairs with adhesive glue

3. Flexible, Semi-Rigid, and Rigid Plastic Bonding

- Bonds to metal, adhesion of repair fillers, and adhesion for metal applications

- Flexible and semi-rigid plastics require surface energy plastics adhesives

Innovations in Adhesive Technologies

- Structural Adhesive Tapes: Featured structural adhesive tapes enhance bond strength in automotive contact adhesive applications.

- Conductive Adhesives: Used in electric vehicle batteries for bonding process in assembly of wires.

- Faster Cycle Times: Faster cycle times lead to improved assembly processes in automotive manufacturers.

Conclusion

Automotive adhesive glue has transformed vehicle manufacturing by offering stronger bond strength, design freedom, and improved fuel efficiency. By understanding adhesive technologies, manufacturers can select the correct adhesive for auto body repair, adhesion for metal, and adhesive with acetone applications.

As adhesive bonds continue to replace mechanical fasteners, the future of automotive adhesives and sealants will focus on environmental performance, exceptional bond strength, and advanced adhesives.

FAQ

What is the best automotive adhesive for metal bonding?

Epoxy Adhesive DP420LH and urethane adhesives offer excellent bond strength for bonds to metal.

Can adhesives replace traditional fasteners in vehicles?

Yes, advanced adhesives provide a powerful bond stronger than conventional fasteners.

How long does it take for automotive adhesives to cure?

Fast-drying adhesives cure within 5-10 minutes, while structural adhesives require 10-15 extra minutes.

Which adhesive is best for automotive plastic surfaces?

Flexible and semi-rigid plastics require surface energy plastics adhesives.

Are adhesives resistant to extreme conditions?

Yes, adhesive technologies ensure resistance to cold temperatures, salt water, and boiling water.