Automotive body technology is a critical aspect of vehicle design that significantly impacts safety, performance, and overall user experience. From advanced materials to innovative manufacturing techniques, the evolution of automotive bodies has been driven by the need for safer, lighter, and more efficient vehicles. But what exactly makes up this fascinating world of automotive body technology? Let’s dive in.

The Importance of Automotive Body Technology

Advancements in Safety

Safety is one of the primary drivers behind innovations in automotive body technology. Stronger materials, crumple zones, and reinforced structures all help protect occupants during collisions. Engineers continually develop body designs that can better absorb impact, reducing injury risk.

Impact on Performance

The body of a vehicle isn’t just about safety—it’s crucial for performance too. The materials used and the body’s design affect the car’s weight, which in turn impacts fuel efficiency, acceleration, and handling. Light but strong materials allow for a perfect balance between performance and safety.

Types of Automotive Body Structures

Monocoque Structure

What is a Monocoque Design?

A monocoque structure is one in which the body itself acts as the frame. This design is used in most modern cars, offering a unified, lightweight structure that can effectively absorb impact.

Benefits of Monocoque Structure

Monocoque designs are known for their lightweight construction, which improves fuel efficiency. Additionally, this type of structure enhances passenger safety due to its better energy absorption in crashes.

Body-on-Frame Structure

How Does Body-on-Frame Work?

Unlike monocoque, the body-on-frame structure separates the vehicle’s body from its frame. This technique is more common in trucks and off-road vehicles, providing strength and durability for rough terrain.

Uses and Advantages

Body-on-frame designs are excellent for heavy-duty vehicles, offering durability for off-road driving. These vehicles can handle more weight and are easier to repair after damage.

Materials Used in Automotive Bodies

Steel and Aluminum

Benefits of Using Steel

Steel is a durable and affordable material commonly used in automotive bodies. Its strength makes it ideal for structural components that must withstand significant force.

Lightweight Benefits of Aluminum

Aluminum is much lighter than steel, which results in reducing the vehicle’s weight and improving fuel efficiency. While it’s more expensive, it has become popular in modern cars, especially electric vehicles.

Composite Materials

Carbon Fiber Reinforced Plastic

This lightweight material is incredibly strong, offering superior performance in high-end cars. Due to its exceptional strength-to-weight ratio, carbon fibre is becoming more widespread.

Fiberglass Use in Cars

Fiberglass is often used in sports cars because it is light and relatively affordable compared to carbon fiber. It helps vehicles achieve high speeds without compromising safety.

Aerodynamics in Automotive Body Technology

How Aerodynamics Affects Fuel Efficiency

Aerodynamics is vital in reducing drag, making the car more fuel-efficient. A well-designed aerodynamic body helps a vehicle slice through the air, minimizing resistance and saving energy.

Aerodynamic Design in Modern Cars

Today’s cars are designed with sleek shapes to maximize aerodynamics. This improves fuel efficiency and enhances overall performance and handling at high speeds.

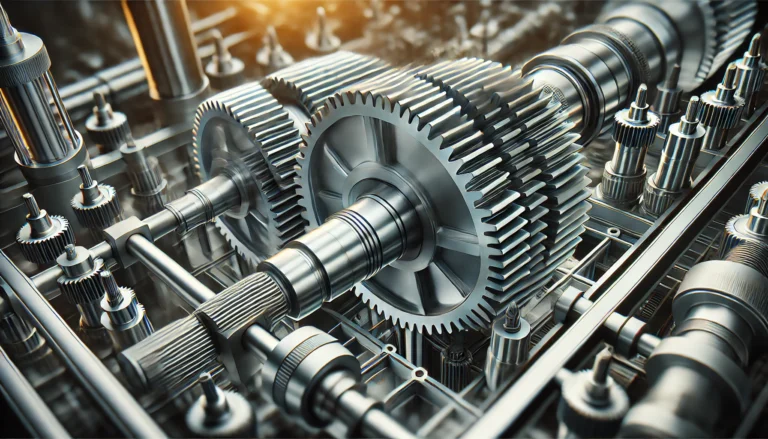

Role of Manufacturing Processes in Automotive Body Design

Pressing and Stamping Techniques

Manufacturing techniques such as pressing and stamping are essential for shaping vehicle bodies. These methods allow for precise construction and high-volume production.

Importance of Precision Engineering

Precision in body construction is crucial for safety and performance. Even minor errors can lead to issues in a vehicle’s alignment, handling, or safety features.

Innovations in Automotive Body Technology

Smart Body Panels

Some cars now have body panels that can sense impacts or even self-repair minor dents. This smart technology enhances vehicle durability and lowers owners’ repair costs.

Lightweight Body Innovations

Manufacturers continuously develop new lightweight materials, such as advanced alloys and composite materials, to improve vehicle performance and efficiency.

Automotive Body Technology and Sustainability

Recyclable Materials in Automotive Bodies

Sustainability is a growing concern in today’s automotive industry. Many manufacturers now use recyclable materials in their vehicle bodies, reducing the environmental impact.

The Push for Energy-Efficient Manufacturing

Energy-efficient manufacturing processes are now essential in reducing the carbon footprint of car production. This shift is key to making the automotive industry greener.

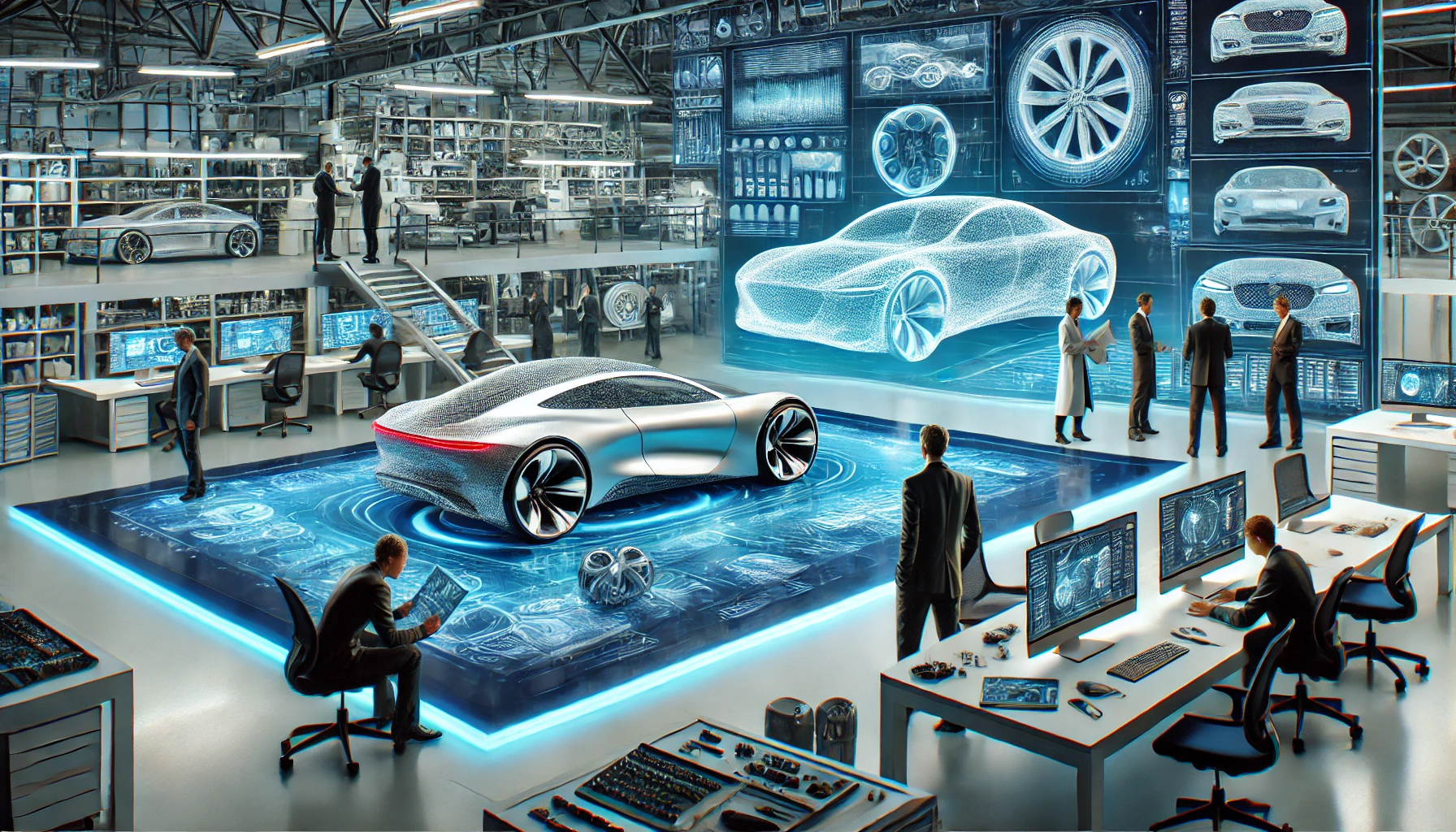

Impact of Technology on Vehicle Design

Autonomous Vehicles and Body Technology

Autonomous cars require advanced body technology, especially regarding sensors and impact protection. Their bodies must integrate with the technological systems allowing them to drive safely.

Electric Vehicles and Their Body Design Needs

Electric vehicles (EVs) require different body design needs than traditional cars. Their heavier batteries require stronger yet lightweight body structures to maintain performance and safety.

Future Trends in Automotive Body Technology

3D Printing in Car Body Manufacturing

3D printing is revolutionizing car body manufacturing, offering faster production times and custom designs. This technology is set to become a standard in the future of car manufacturing.

Nanotechnology in Car Bodies

Nanotechnology could make car bodies even lighter and more robust. Researchers are exploring ways to use nanomaterials in automotive bodies, which could lead to groundbreaking innovations in strength and durability.

Challenges in Automotive Body Development

Meeting Safety Standards

As body technology advances, meeting global safety standards remains a significant challenge. Engineers must balance innovation with the need for compliance.

Balancing Cost and Innovation

Innovative materials like carbon fibre are expensive. For manufacturers, finding the right balance between cost and cutting-edge technology is crucial.

The Role of AI in Automotive Body Engineering

AI for Design Optimization

AI is increasingly used to optimize automotive body designs, improving aerodynamics, material efficiency, and safety features.

Machine Learning in Material Selection

Machine learning helps manufacturers select the best materials for specific vehicle parts, ensuring that each component meets performance and safety requirements.

How Automotive Body Technology Impacts the Consumer Experience

Safety Features from Body Technology

Thanks to advances in body technology, modern vehicles come equipped with features like crumple zones and advanced airbags that enhance passenger safety.

Comfort and Noise Reduction

New materials and designs also contribute to quieter and more comfortable rides, improving consumers’ overall driving experience.

Case Study: Tesla’s Approach to Automotive Body Technology

Tesla’s Gigacasting Process

Tesla’s revolutionary gigacasting process allows for creating large, single-piece body components. This innovation reduces manufacturing time and costs while increasing structural integrity.

Tesla’s Use of Aluminum and Composite Materials

Tesla extensively uses lightweight materials like aluminium and composites in its cars. This improves performance and boosts energy efficiency, a critical factor in electric vehicles.

Conclusion

The evolution of automotive body technology continues pushing the boundaries of what vehicles can achieve. From safety to performance, materials to manufacturing, this field is central to the future of the automotive industry. As we move towards more sustainable, efficient, and autonomous vehicles, innovations in body technology will remain at the forefront of automotive design.

FAQ

What is automotive body technology?

Automotive body technology involves the materials, design, and manufacturing processes used to create vehicle bodies.

What are the most common materials in automotive bodies?

Common materials include steel, aluminum, carbon fiber, and fiberglass.

How does body technology impact vehicle safety?

Advanced body designs improve crash protection, incorporating crumple zones and reinforced structures.

What is the role of aerodynamics in automotive body design?

Aerodynamics reduces drag, improving fuel efficiency and vehicle handling.

What future trends are expected in automotive body technology?

Future trends include 3D printing, nanotechnology, and more sustainable materials.